SG 111s restoration project

Publié : 09 Nov 2010, 16:56

Hi my name is Alexander i live in the Netherlands.

I don't speak French but i hope some one still can help me out. I got this SG car a few weeks ago and i am planning to restore it. It has a super tigre .21 engine on it and 2 old servo's.

I have a few questions.

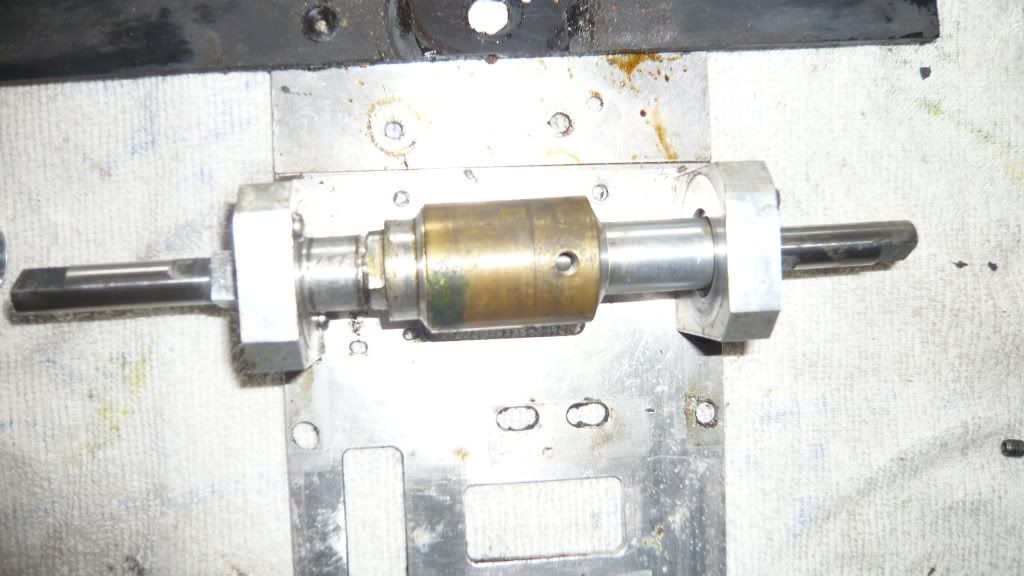

I dissasembled the car but i don't see how i can open up the differential. Is there a special way? I unscrewed one screw that is in the copper housing but i i can still not open it Does anyone know how to do that? Do i just have to use a lot of force?

Does anyone know how to do that? Do i just have to use a lot of force?

The metal pod seems to be bent a little where the epoxy plate is screwed onto. I think i can just make it straight again by hammering it a little?

The gas tank is also missing the cap. Is there a good replacement for it?

The spur is still in good condition but can i get spares from somewhere?

I didn't make any pictures during dissasembly cause the car was very dirty and oily. I will make some pictures of the proces soon.

With regards,

Alexander

online translation:

Salut mon nom est Alexandre.

Je ne parle pas français, mais j'espère que quelqu'un peut-encore m'aider. SG j'ai eu cette voiture il ya quelques semaines et je me prépare à le restaurer. Il a un super tigre 0,21 moteur sur elle et deux servos vieux.

J'ai quelques questions.

Je dissasembled la voiture mais je ne vois pas comment je peux ouvrir la différence. Y at-il une manière particulière? Que je dévissé une vis dans le boîtier en cuivre, mais encore peut-ii pas à l'ouvrir:?: Est-ce que quelqu'un sait comment faire cela? Ne i suffit d'utiliser beaucoup de force?

Le pod métal semble être un peu Où sont la plaque époxy est vissé échec. Je pense que je peux le rendre droit nouveau par martelage un peu?

Les Spurs sont toujours en bonne condition, mais puis-je obtenir de pièces de rechange de quelque part?

Toutes les images je n'ai pas toujours dissasembly cause de la voiture était très sale et huileuse. Je vais faire quelques photos du processus bientôt.

En ce qui concerne,

Alexander

I don't speak French but i hope some one still can help me out. I got this SG car a few weeks ago and i am planning to restore it. It has a super tigre .21 engine on it and 2 old servo's.

I have a few questions.

I dissasembled the car but i don't see how i can open up the differential. Is there a special way? I unscrewed one screw that is in the copper housing but i i can still not open it

The metal pod seems to be bent a little where the epoxy plate is screwed onto. I think i can just make it straight again by hammering it a little?

The gas tank is also missing the cap. Is there a good replacement for it?

The spur is still in good condition but can i get spares from somewhere?

I didn't make any pictures during dissasembly cause the car was very dirty and oily. I will make some pictures of the proces soon.

With regards,

Alexander

online translation:

Salut mon nom est Alexandre.

Je ne parle pas français, mais j'espère que quelqu'un peut-encore m'aider. SG j'ai eu cette voiture il ya quelques semaines et je me prépare à le restaurer. Il a un super tigre 0,21 moteur sur elle et deux servos vieux.

J'ai quelques questions.

Je dissasembled la voiture mais je ne vois pas comment je peux ouvrir la différence. Y at-il une manière particulière? Que je dévissé une vis dans le boîtier en cuivre, mais encore peut-ii pas à l'ouvrir:?: Est-ce que quelqu'un sait comment faire cela? Ne i suffit d'utiliser beaucoup de force?

Le pod métal semble être un peu Où sont la plaque époxy est vissé échec. Je pense que je peux le rendre droit nouveau par martelage un peu?

Les Spurs sont toujours en bonne condition, mais puis-je obtenir de pièces de rechange de quelque part?

Toutes les images je n'ai pas toujours dissasembly cause de la voiture était très sale et huileuse. Je vais faire quelques photos du processus bientôt.

En ce qui concerne,

Alexander